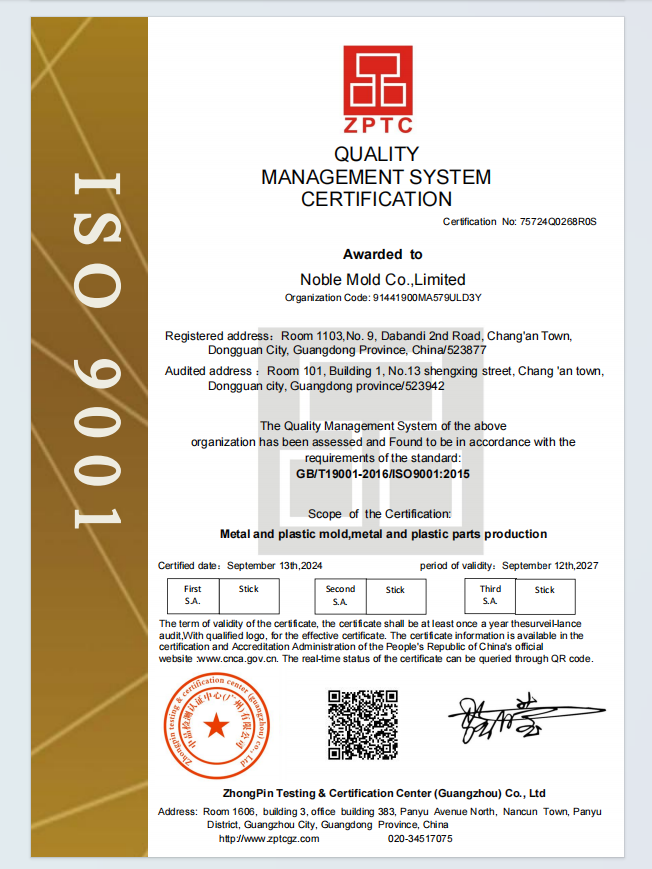

Noble-Mold has a documented quality system designed to be compliant to lSO9001:2015.

We ensure the quality of your molded parts from conception to completion. With

feasibility studies, design reviews, process capability studies, preventative

maintenance and training, we prevent problems before they arise. Success comes from

taking care of the little things while not losing sight of the over-all-picture.

Attention to details is the difference between compliant and complaint. Satisfying

our customer’s molding needs is our foremost occupation. This requires a program of

continuously improving the process, the product, and the people. Our customers expect

nothing less and it’s the only way to do business we know.

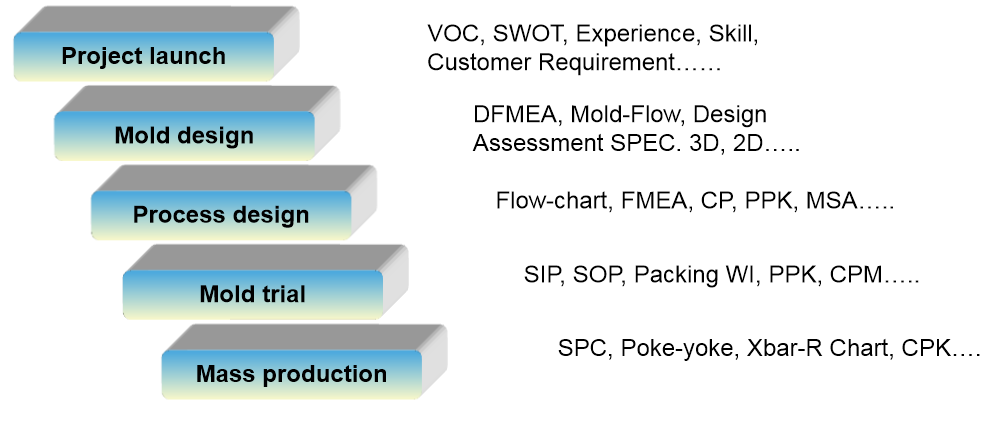

Noble-Mold Quality system can provide:

PPAP capabilities Full documented layout inspections

IQC, IPQC, OQC for the mould manufacture

IQC,IPQC, FQC, OQC for the Plastic manufacture

Quality Tools; APQP, PPAP, FMEA, MSA, SPC, PPK/CPK,

Control Plan, Flow-Chart, QC seven tools, QFD, IMDS, REACH, WEE

Medical devise special tool; Process validation(IQ, OQ, PQ), MSDS, FDA,

CE, ROHS, COC, Batch traceability management, Clean workshop management

Quality Control

Use special quality tools to analysis and solve quality problem in production process,

such as PPK/CPK,MSA, SPC, PPAP, APQP, FMEA, Control Plan, DOE, QFD etc.

APQP&PPAP&Quality Tools: